RIFLE SCOPE MAINTENANCE

When buying a scope, most people will ask questions regarding light gathering capabilities, reticle type, and ease of use.

However, often overlooked is the question: is the scope nitrogen filled?

We know that when moist warm air hits a cold surface, such as a lens, it forms small water droplets. This is okay when it is on the outside of the glass, but when it is on the inside it causes problems.

Nitrogen is an inert gas, heavier than air and has greater density, making it less susceptible to temperature changes. It’s high purity also makes it drier than air, preventing moisture damage to the coated lens surface and decreasing the chance of corrosion. It also acts as a pressure barrier preventing any micro particles from adhering to the lenses and thereby pushing them to the inside of the coated tube during assembling.

All scopes are susceptible to temperature change and consequently, pressure loss over time. Nitrogen is there helping to keep moisture at bay - keeping your scope clean and dry will help prolong it’s optical quality.

THREE TOP TIPS FOR RIFLE SCOPE MAINTENANCE

Never Spray Oil on Your Scope.

This is common in-home practice to prevent the steel tube from rusting. However it is far better to wipe the scope down with a cloth that has had a light oil applied to it, such as this one. Spraying will cause oil particles to work into the tube - something we often see when disassembling for service.

One of the best ways to prevent any moisture present from doing further damage is to store your device with a desiccant (silica gel), placed in a container close to the optics.

Windage and Elevation Adjustment.

The movement of these components can become stiff overtime, so I recommend giving them a turn occasionally. Count the number of turns you do to make it easy to return to the central position. You may then need to do a bore sight prior to your next use.

A number of scope manufacturers nowadays use only a single opposing spring to compensate for the adjustment, which can cause travel issues and often soften over time due to the constant pressure exerted on it. If your scope is not going to be used for an extensive period, it is worthwhile to lessen this pressure by backing off the windage and elevation adjusters.

Cleaning Lenses

Never clean your lens with your handkerchief! Always gently blow to remove any grit or particles or preferably use a puffer brush (available from camera/computer stores). This will remove the small particles that can otherwise cause scratches on the lens coating and thus change the refractive order of the lens. Once clean, gently spray with a recommended brand of isopropyl alcohol (lens cleaner) then apply a lint free cloth or lens tissue paper to remove any excess marks or grease.

Optical Repairs Services.

We have been offering a comprehensive range of optical repairs for over 30 years. We repair and overhaul a wide range of optical devices which include both vintage and more current types of riflescopes , binoculars and the like.

We also specialize in repairs of large telescopic gun sights, laboratory microscopes and even precision refractor heads as used by your optometrist to measure the refractive disorder of your eyes.

We predominantly specialise in the older European optical devices, however we will gladly look at most problems to see if they can be repaired or overhauled and all evaluations are at no cost.

Our customers over the years have come from wide and far. UK, Canada, USA, South Africa, New Zealand and we have also carried out work for the Australian Maritime Service, Australian Federal Police, QLD Governor General and a number of Specialised Hospitals and Clinics associated with Eye disorders both in Australia and overseas.

HISTORY

THE RIFLE SCOPE

The scope in various forms has been with us since the early 1600’s, when Dutch inventor, Hans Lippershey, was accredited with the first known telescope. Over the years there were numerous developments on optical lenses, the most significant being the achromatic lens (two part lens - Crown and Flint). Although patented by John Dolland in 1753, it was in fact amateur optician, Chester More Hall, who in 1733 proved Newton’s statement incorrect: “that chromatic aberration correction through a lens was not possible”. This significant development in optics allowed for wave lengths of light, which have different focal properties to diminish the effects of light scatter, to be more controlled and thus reduce chromatic aberration. This led to the apochromatic lens, which coincidentally was developed and patented by Peter Dolland (John Dolland’s son) in 1763. These developments in lens correction and the increase of uninterrupted light transmission were the foundation for all optical systems of rifle scopes as we know them today.

The rifle scope first appeared around 1835 and was developed by American, Morgan James, in collaboration with John Chapman who discovered his invention. This led to the first commercially available sight which was called the ‘Chapman James Sight’. These long tube scopes had no adjustments for height or windage, and were constructed using thin copper or brass sheeting, which was malleable and thus able to be rolled to form a tube-like construction and then soldered down the joint seam. The lenses were then inserted and this became the rifle scope as we know it today. This in turn was mounted onto the rifle. The optical power was low, probably around 1–2x magnification, but the point was that the huntsman could now view his subject more clearly.

Then around 1853, William Malcolm started to produce scopes using achromatic lenses together and incorporating windage and elevation adjusters for the outside of the tube. This was a huge improvement for the rifle scope. These scopes, along with those that were produced by Lee Amidon (The Vermont Sight), were the standard scope used during the American Civil War.

Then as further advancements in optic design evolved, so too did different manufacturers, which resulted in different designs and styles of scope bodies. As the optical manufacturing quality improved, advancements in the sighting mark (reticle) followed.

The first types of reticles that were used in the earlier Malcolm scopes were just a rudimentary fine wire vertical post soldered onto a brass ring and inserted into the tube. They then found that by adding a horizontal wire to cross the post, this gave the marksman a better orientation. This improvement to the reticle and their design had a great effect on both sides of the campaign during the Civil War.

A Typical Malcolm 3x of the 1800’s Ref:-The Winchester Sutler, Inc. * Brush Creek Armory- www.winchestersutler.com

THE RETICLE

The reticle was first produced using primitive materials such as spider webs or even horse hair to obtain the sighting cross. Then with the advent of the industrial revolution, materials were able to be produced with greater accuracy and treated steel wires of less than 1/25inch (.040mm) were used.

However as the improvements to the optics were made and larger lenses were introduced to increase light transmission, it created a problem with heat build up inside the tube and caused the reticle to distort. The larger lens or objective is similar to a magnifying glass. The light enters and converges at a focal point (and we all know how hot that focal point gets, when the sun shines and your hand is in the way).

Although the first etched reticle was produced around 1700, the accuracy and finer detail required for a scope did not evolve until the mid 1800’s. There were a few different methods to produce an etched reticle. The first was by hand; using a diamond blade and then filling in the scored line with graphite and coating it with a form of clear lacquer. Later they started to produce reticles using chemical etching, which made the outline more defined, thus producing finer detail. This process involved bitumen being coated onto the glass and a ruler to draw a fine line or mark on the bitumen. This small piece of glass was sometimes no bigger than 5mm in diameter and would then be dipped into hydrochloric acid and washed in alkaline solution. The bitumen was then removed to reveal the fine lines, chemically etched into the glass. After polishing, the etched line was in-filled to define the mark of the outline and covered in a clear non-reflective lacquer.

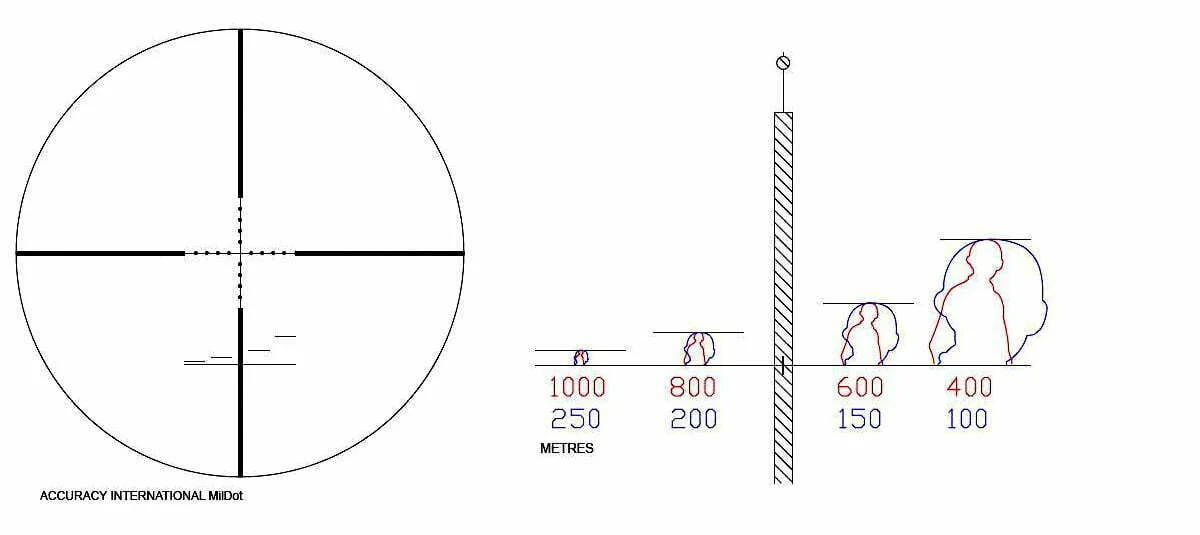

This process was further developed by the British prior to WW1 and was applied to an array of different optical devices with great success. This included binoculars, rangefinders and gun sights (which incorporated the first forms of the Mill dot style reticle for improved accuracy and determining the range of the target). Other descriptions used for this pattern of fine lines include graticule or reticule. The development of the photographic etching followed, which is a more complex process that greatly improved the designs and styles of scopes that are in common use today.

The laser etched style reticle can be found on most modern scopes today. Up until only 10 years ago, precision glass reticules were only available on your more expensive brands of scopes. However we are now seeing them being fitted to the lower end brands. The advantage is that they are obviously more stable and less susceptible to heat distortion or shock treatment (within reason). The downside is that they can collect microscopic particles on the surface, which may be floating in the tube, and hence obscure the field of view. Another common problem they are susceptible to is the easy occurrence of watermarking, due to temperature changes in the tube. The standard wire reticle, which is fabricated mostly from either one or two metal sheets or wires, is not as robust and is susceptible to heat change and furring (caused by electrolysis when two dissimilar metals are used in construction).

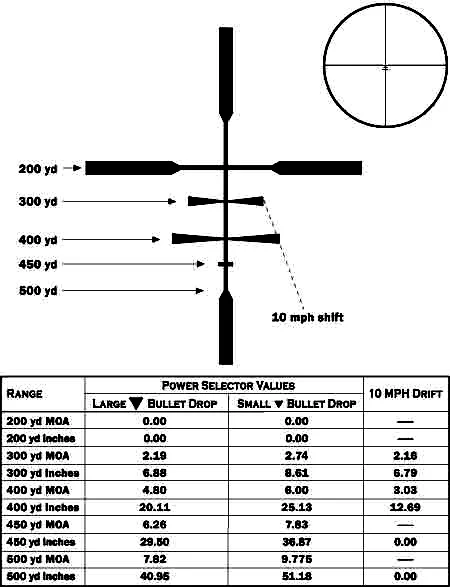

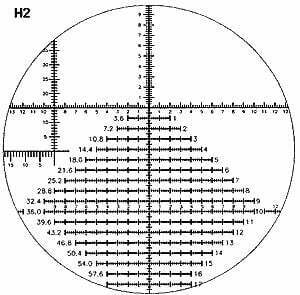

The detail and information we can obtain from a reticle today is exceptional. The reticle below is a Bone and Crocket commonly used in Leupold scopes and no more than 15mm in diameter.

THE SCOPE OF TODAY

There have been significant improvements over the years in lens development and corrections: the introduction of multi coatings and changes to the compounds of the glass, together with the way they are ground and polished. These improvements have significantly improved the physical properties of light transmission, especially when the light on the subject you’re observing is poor.

We have also seen over the last 30 years: improved angles of observation, longer eye relief, etched reticle systems and illuminated reticles. There has also been the adjustable objective to elevate parallax disorders, and more recently the addition of a side compensating lens for easier parallax control. There is even the possibility that dual range monitoring through the eyepiece will be a reality one day. All these developments, together with other functions and features, enhance the observer’s activity, and attain greater accuracy for the user.