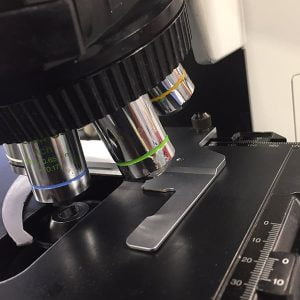

Microscope Servicing

At Optical Repairs we offer you the best in microscope servicing and repairs, and aim to repair or maintain instruments to their full optical potential irrespective of age, make or model.

Our services are cost effective across the range, from individual use microscopes all the way to multiple units (which require regular preventative maintenance). We can offer either on-site repairs and maintenance or for more complex issues we have a dedicated workshop facility.

We would be delighted to discuss your service or maintenance requirements and how we can assist in keeping your optical equipment functioning correctly, and potentially prolong it’s lifespan.

Whether it’s a microscope or other optical device used solely by yourself, or several units that require a periodic preventative maintenance (PM) plan, please feel free to contact us to discuss the most cost-effective way in which to keep it operating correctly and optimally maintained.

Details of Routine Servicing Include:

- Initial inspection of instrument and check of general functionality

- Removal of all optical components (including objective lenses or magnification system)

- Remove stage, condenser base diaphragm and any light diaphragm or filter assembly

- Clean all optical components and check for any optical correction requirements

- Remove prisms from binocular head chamber and inspect for any fungal growth

- Advise and quote accordingly and replace only if required

- Clean chambers, remount prism blocks and collimate to manufacturer's specifications

- Final inspection at varying magnifications

- Disassemble stage and remove any old lubricants

- Reassemble and repack lubricant accordingly

- Adjust stage tensions to specifications or user preference

- Disassemble, lubricate and reset, focusing on both course and fine to factory specifications

- Disassemble condensers if applicable and clean, re-align for correction

- Disassemble phase condenser assembly and clean

- Re-align optics and illumination correction for use on Phase/DiC and Fluoro

- Clean/check/test and set the electrical system to ANZ/NZ 3760:2010 specifications

- Final optical and mechanical inspection and checks

- Individually test each microscope with an appropriate test slide under all power settings

- ULO MK II 6 Brand Certified Test Slider for accreditation

- Final test reports and service/accreditation schedule completed